Solid preparation workshop

publisherXavier

time2019/11/07

- Commonly used solid dosage forms include powders, granules, tablets, capsules, pills, films, etc.

1. Commonly used solid dosage forms include powders, granules, tablets, capsules, pills, films, etc.

Second, the tablet synthesis process is: raw and auxiliary materials - external clear - temporary storage - crushing, sieving - weighing - mixing, granulation - drying - granule transfer - tableting - coating - drying, inspection - inclusive - - Outsourcing - finished product; the synthesis process of capsules is: raw and auxiliary materials - external clearing - temporary storage - crushing, sieving - weighing - mixing, granulation - drying - granule transfer - capsule filling - capsule polishing - inner packaging - outsourcing - finished product Storage; the synthesis process of granules is: raw and auxiliary materials - external clearing - temporary storage - crushing, sieving - weighing - mixing, granulation - drying - granule transfer - granule packaging - outsourcing - finished product storage. Since tablets, capsules, and granules are processed in the same stage before the production, the production lines of tablets, capsules, and granules are arranged in the same clean area, which can improve the utilization rate of the equipment and reduce the clean area. Area, thus saving construction funds. Three production lines of tablets, capsules and granules are arranged in the same clean area. When arranged in a plane, they are arranged in sections according to the production section. From the dry granules, they are divided into three processes, which are respectively directed to tablets, capsules and granules.

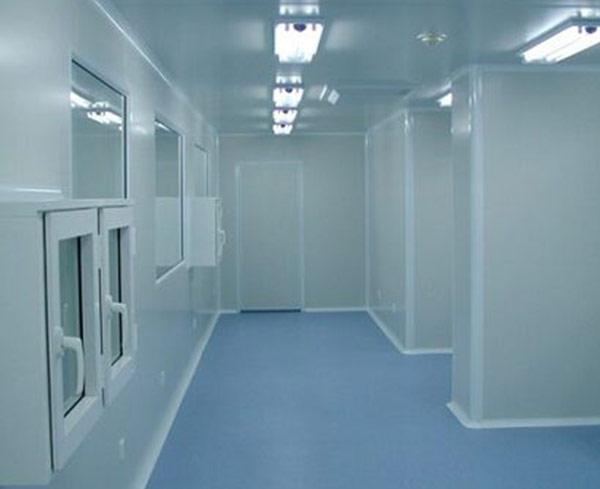

Design purpose Firstly, it meets the industrial production requirements of pharmaceuticals and provides layout according to the production process of pharmaceuticals. Secondly, the “Good Manufacturing Practices” (GMP) is the basic norm for drug production and quality management. The central idea is that the form of any drug quality is produced, not tested. Therefore, the purpose of plant design is to provide a qualified layout and reasonable production site for pharmaceutical production based on the idea of GMP. According to the design of the solid preparation workshop, the design is based on the “Good Manufacturing Practices” (1998 Revision), “Design Standard for Cleanrooms in the Pharmaceutical Industry” (GB50073-2001) and the State on Construction, Fire Fighting, and the National Food and Drug Administration. Environmental protection, energy and other aspects of the norm. 2.2.4 Design Principles 1 The layout of the workshop shall be as close as possible to human and logistics, and shall not flow back, in accordance with the relevant standards and specifications for GMP safety and fire prevention. And pay attention to the rationality of the layout, convenient transportation and short route. 2 Select advanced production technology and equipment at home and abroad to improve product quality and production efficiency. 3 purification air conditioning and comfort air conditioning system can effectively control the wet temperature; advanced water production process, water quality meets the requirements. 4 Strictly abide by the current safety regulations and adopt various effective and effective accident prevention and treatment measures