Daily Maintenance And Common Failure Analysis Of Capsule Filling Machine

publisherSteve

time2020/05/12

- In the pharmaceutical industry, the capsule filling machine is a kind of commonly used equipment, which can carry out automatic transmission, seeding, filling, locking and other processes for capsules.

Daily Maintenance And Common Failure Analysis Of Capsule Filling Machine

In the pharmaceutical industry, the capsule filling machine is a kind of commonly used equipment, which can carry out automatic transmission, seeding, filling, locking and other processes for capsules.

Therefore, there is a high correlation between kinematic precision and mechanism, and its kinematic and dynamic characteristics are related to the performance of the whole machine. Therefore, the daily maintenance of the capsule filling machine is particularly important. In this regard, the author combs out some knowledge of the daily maintenance of the capsule filling machine and the analysis of common faults.

The daily maintenance of the equipment can guarantee a longer service life. During the daily maintenance of the capsule filling machine, it should be noted that when the normal working time of the machine is long, the parts and components that are in direct contact with the drugs should be cleaned regularly; when the batch of drugs is changed or the stopping time is long, it is also necessary to clean them.

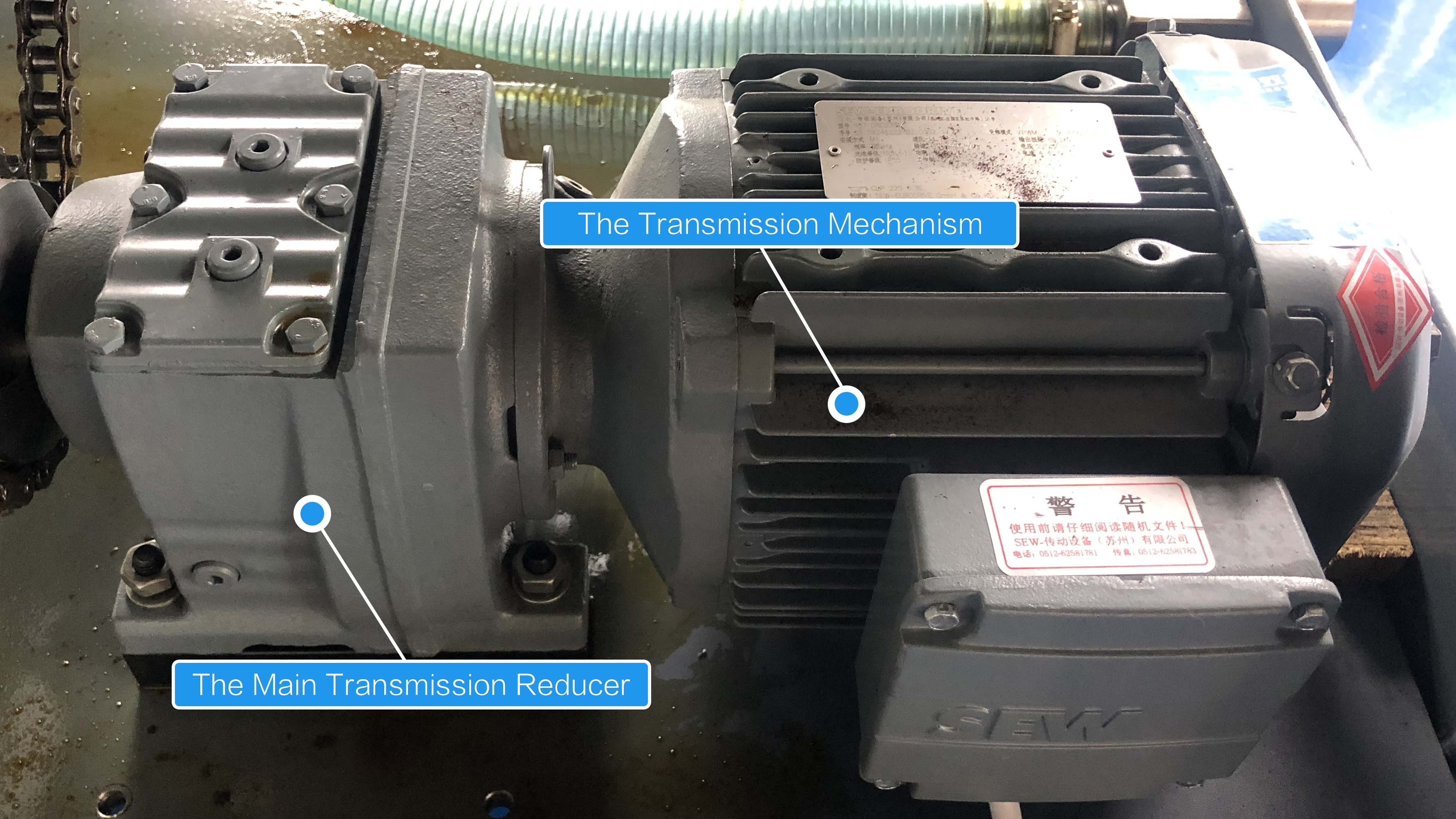

In addition, it is pointed out in the industry that the transmission mechanism under the platform of the capsule filling machine should be regularly and appropriately added with lubricating oil (grease) to reduce the wear of the moving parts; the oil quantity of the main transmission reducer should be checked once a month, and the lubricating oil should be added in time when it is insufficient, and the lubricating oil should be replaced once a half year; the transmission chain bar should be checked once a week, and an appropriate amount of lubricating grease should be added, and it is necessary to tighten it again.

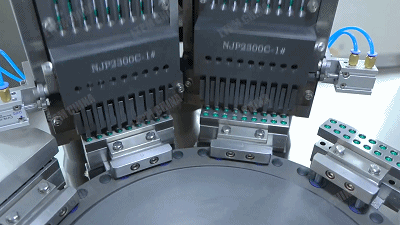

Abnormal one, the capsule can not be separated. According to the user's report, in the operation of the capsule filling machine, there are often cases where the capsule can not be separated. In view of this situation, analysis and reprocessing are generally needed.

Specifically, if it is the cause of the capsule itself, the capsule needs to be replaced; if it is a vacuum pump problem, the vacuum pump can be repaired or replaced. For example, when the air pipe separated from the vacuum pump connecting the capsule is broken, replace the air pipe; when the filter membrane of the vacuum pump is blocked, clean the filter membrane, etc.

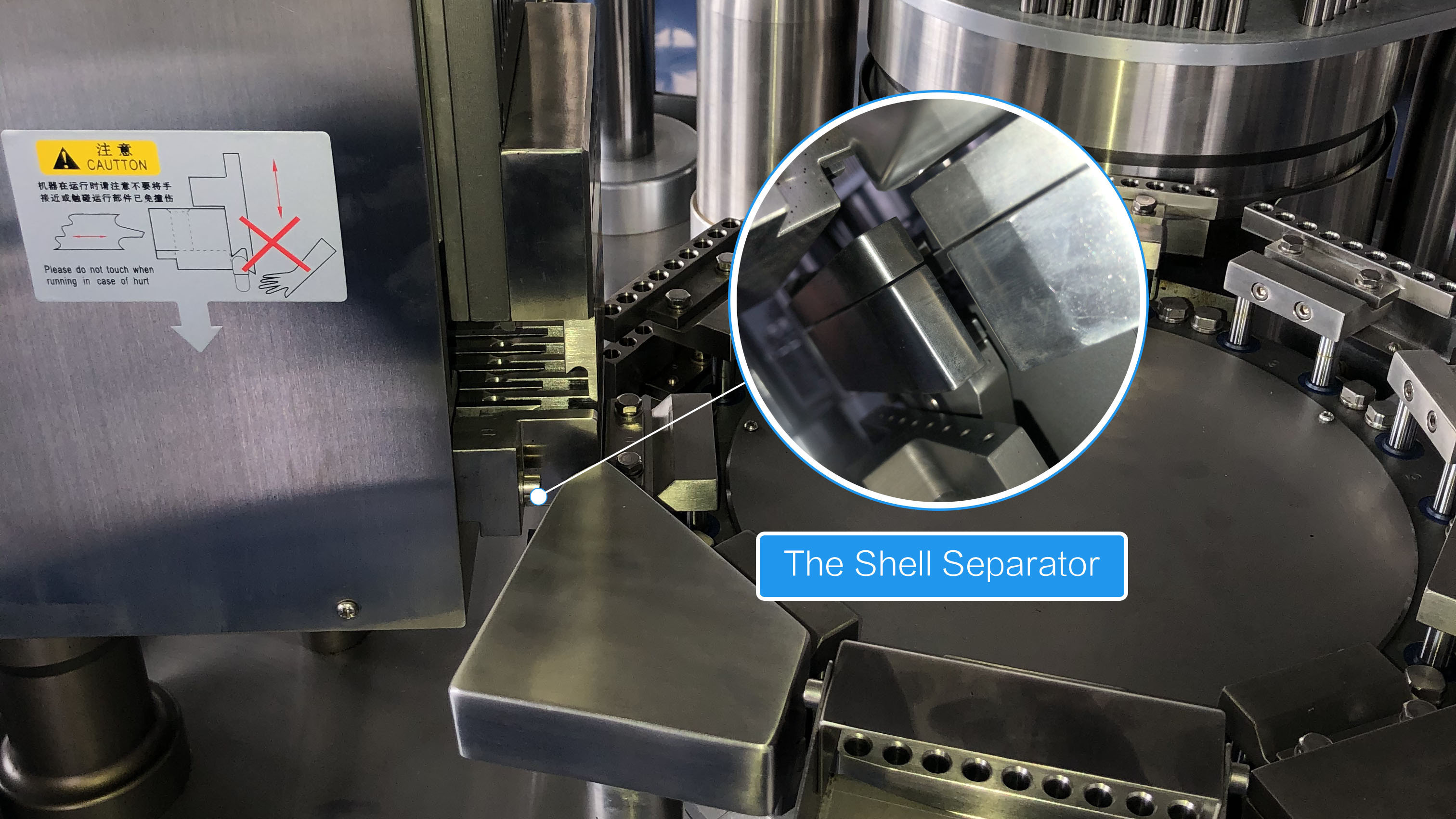

In addition, too much clearance between the module and the shell separator will also cause the shell cannot be separated. Relevant technicians said that in this case, either adjust the height of the shell separator, or there is a problem with the module or the expansion bar in the module. Specific analysis is needed. For example, when the powder is too sticky, it is easy to block the module. At this time, the module needs to be cleaned.

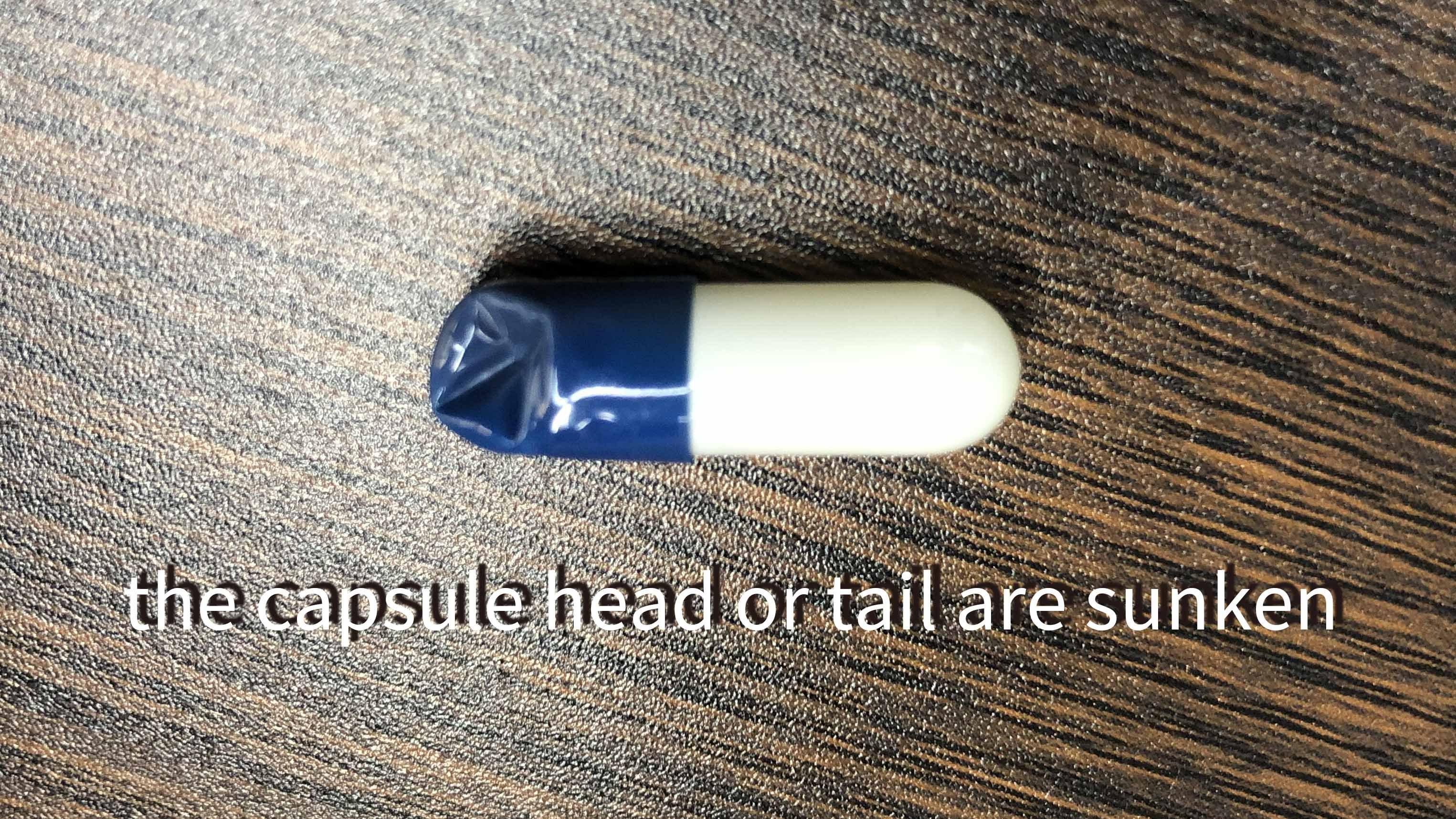

Second, the capsule head and tail are sunken. The technician said that this situation is generally due to the problem of the capsule itself, which can be solved only by replacing the capsule. At the same time, it is necessary to check the position of the thimble and whether the height of the thimble needs to be adjusted.

In addition, the problem can be solved by increasing the stress area of the capsule.

Abnormal three, capsule wipe split. According to the user, this is a headache and a problem that users often encounter during operation. There are several reasons for this phenomenon.

This includes the causes of the capsule itself, such as the large difference between the capsule cap and the capsule body. At this time, the capsule needs to be replaced. The second reason is that there is too much powder left on the module, so the module needs to be cleaned.

When installing the module, the upper and lower modules are not aligned, so the module needs to be aligned again. Until the debugging rod can automatically fall into place.