How to debug the medicine tablet machine Three simple tutorials are worth referring to

publisherSteve Chan

time2020/07/30

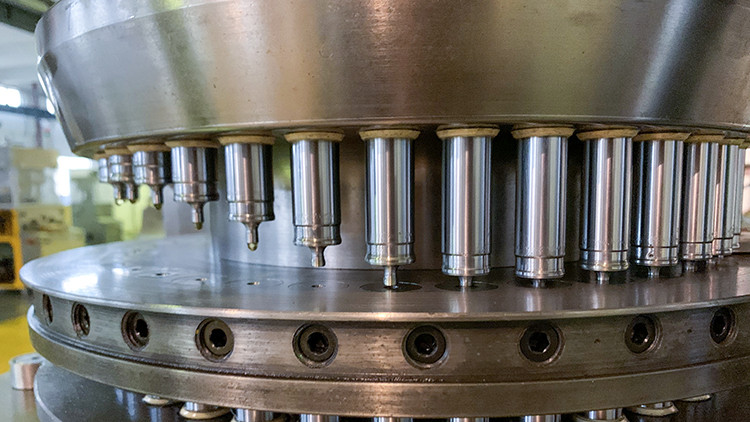

- The tablet press is a machine that puts granular or powdery materials in the die hole and presses them into tablets.

The tablet press is a machine that puts granular or powdery materials in the die hole and presses them into tablets. It is especially suitable for small batch production. Its characteristics are adjustable speed, material filling depth, tablet thickness, The machine is equipped with a mechanical buffer, which can avoid dust generated during operation, prevent adhesion and blockage, and can recycle raw materials for reuse.

The industry pointed out that in order to meet the requirements of storage, transportation, preservation and disintegration time limit, there are corresponding requirements for a certain dose of pressure during tablet compression, otherwise the actual thickness and appearance of the tablet will be affected. Therefore, pressure adjustment during tablet compression is essential. The user generally needs to debug the equipment when using the tablet press. There are three specific tutorials.

Film adjustment

This method is to first turn the hand wheel to make the lower punch up to the position, and observe whether the lower punch surface is aligned with the plane of the middle mold (either high or low will affect the output). If not, loosen the butterfly screw and loosen it. The gear pressing plate conveys the upper adjusting gear so that the lower punching surface is aligned with the plane of the middle mold, and then the pressing plate is still pressed on, and the butterfly screw is tightened.

After the completion, the user can shake the hand wheel by hand and run the empty car for more than ten revolutions. If the machine is running normally, it can add material to test the pressure and proceed to the next adjustment.

Adjustment of filling depth

According to the industry, the adjustment of the filling depth is the adjustment of the weight of the tablet. The method is: first loosen the thumb screw and loosen the gear pressing plate. Turn the lower adjusting gear to the left to raise the lower punch rod, and the filling depth is reduced (the tablet weight is reduced). After adjustment, press the gear tooth pressure plate and tighten the butterfly screw.

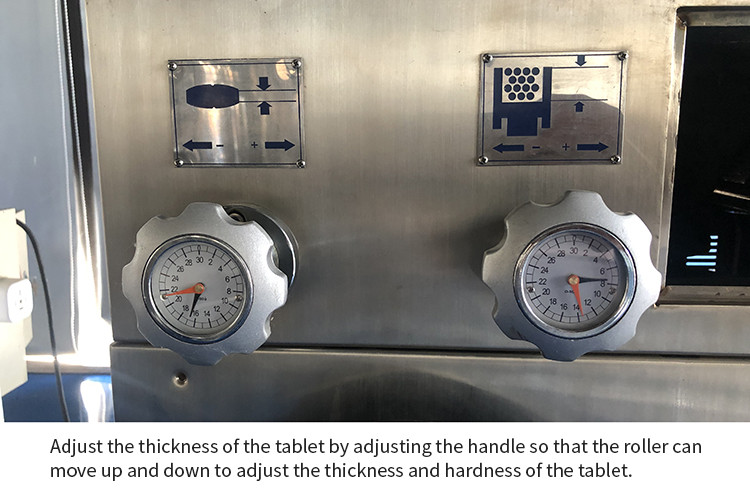

Pressure adjustment

The pressure adjustment is the adjustment of the tablet hardness. First, loosen the connecting rod lock nut, turn the upper punch rod, and turn to the left to move the upper punch rod downward. The pressure will increase and the hardness of the tablet will increase; otherwise, Turning to the right will reduce the pressure and the hardness of the tablet. After adjustment, use a wrench to clamp the lower hexagon of the upper punch rod, and then tighten the connecting rod lock nut.

When the adjustment of the die is basically completed, restart the motor to test pressure more than ten pieces, check the weight, hardness and surface finish of the pieces and if they are qualified, they can be put into production. During the production process, the quality of the tablets must be checked at any time and adjusted in time.

In addition, in order to make the medicine tablet press work better and stably, users also need to pay attention to the maintenance and maintenance of the equipment. For example, pay attention to the lubrication of the friction surfaces of the moving parts. Before use, all the oil cups, oil holes and friction surfaces must be lubricated, and run empty to make the friction surfaces covered with oil film, and then put into use; regular inspections Whether each screw is loose, you should also pay attention to check it frequently during the working process. If there is any looseness, tighten it immediately to avoid malfunction.