What are the common failures of using semi-automatic capsule filling machines?

publisherSteve

time2021/01/06

- The common faults of semi-automatic capsule filling machine are described below. The vibration of capsule filling machine is not ideal and the voltage is adjusted. Reed screw loose, tighten screw. The capsule shell is arranged in the workbench plate, the mouth is high or low, and the dislocation plate and guide rail are adjusted.

What are the common failures of using semi-automatic capsule filling machines?

The common faults of semi-automatic capsule filling machine are described below. The vibration of capsule filling machine is not ideal and the voltage is adjusted. Reed screw loose, tighten screw. The capsule shell is arranged in the workbench plate, the mouth is high or low, and the dislocation plate and guide rail are adjusted. The capsule shell has too many inverted heads (more than 3%), the vibrator is not adjusted properly, because the appropriate voltage or the size of the capsule shell is not up to standard, the qualified capsule shell is selected. Capsule shell stuck on the plate can not fall, replace capsule shell or adjust the position of dislocation plate and plate hole.

Mold can not be reset in the track, guide rail back-end pressure spring stuck or capsule variant stuck. Reinstall the spring or top rod and push the stuck capsule down. The wear of the guide plate in the mould affects the low rate of capsule sleeve, the replacement of the new mould of the capsule filling machine or the loosening of the positioning on both sides, the fastening of the positioning nail, the modification or humidity of the capsule, and the replacement of the capsule shell.

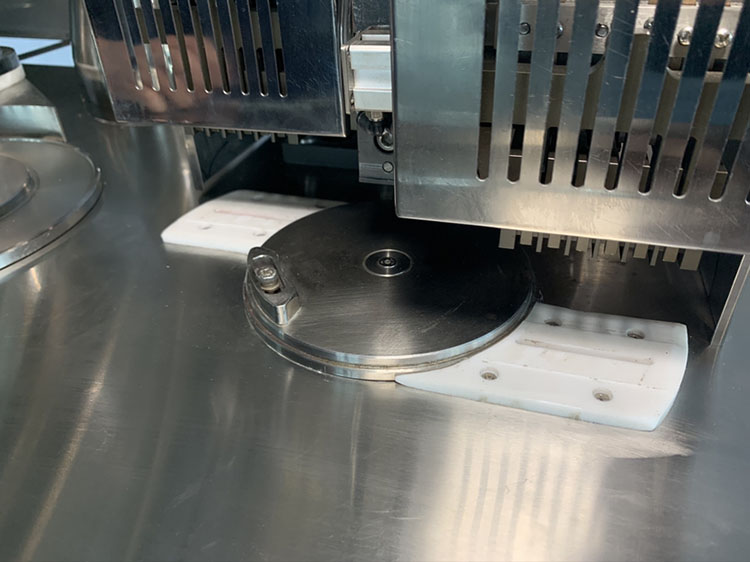

LTPM CHINA Semi-automatic capsule filling machine is suitable for filling of 000#- capsule cap, body and powder. It is suitable for small and medium-sized pharmaceutical factory, health product factory, hospital, veterinary medicine factory, research institute, laboratory, pesticide factory and small and medium-sized batch production of pharmacy with more patients. Using hole plug filling, intermittent operation, frequency conversion speed regulation, suitable for powder rotation or pellet capsule tablets to automatically complete the seeding, sub-capsule, filling (waste capsule removal), lock capsule, finished product output and so on.

All parts of contact with drugs are made of stainless steel precision, with dust cleaning device to meet the "GMP" standard requirements.