DLL-160 Alu Alu Capsule pill Tablets Blister Packing Machine equipment

- FOB Price

US $13800.001 - 1 piece

US $13800.002 - 2 piece

- group name

- Blister Packing Machine

- Min Order

- 1 piece

- brand name

- LTPM CHINA

- model

- DPP-88

- Nearest port for product export

- Ningbo

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Westem Union

- update time

- Fri, 27 Sep 2019 11:27:57 GMT

Paramtents

Model DLL-160

Speed of drum (rpm) 7-15 stepless adjustable

Capacity (pcs/h) 10,000-45,000 pcs/h

Max. Packing Width (mm) 160mm can be manufactured as user's requirements

Alu for Medicine(mm) 0.15-0.1×160

AL/PL Complex Film(mm) 0.08×160

Hole die of Reel (mm) 40-45

Electro thermal Power 1kw×2

Main Motor (kw) Main Motor (kw)

Air Pressure (Mpa) 0.4

Air supply ≥0.1m³/min

Overall Dimensions(mm) 1250×600×1470(L×W×H)

Weight (kg) 900

Packging & Delivery

-

Min Order1 piece

Briefing

1. Easy Installation and Operation

2.Automatically Feeding

3.High Speed

4. Alu Alu Blister Packing

Detailed

DLL-160 Alu Alu Capsule pill Tablets Blister Packing Machine equipment

Application:

It is designed with success to meet the needs in the market by our own research fellows. It has PLC Human interface, frequency converter, higher automation, easy operation, beautiful style, full function, well performance and durability. It conforms to "GMP" standards.

Features:

1. Vibration feeder and crisp remover can effectively remove the powder and crisps inside medicine.

2. Auto counting, horizontal perforation, slitting, waster-side cutting, printing batch number and auto punch etc functions can be achieved automatically in one process.

3. The diameter of heat pressing cam can be changed from 110 to 140 mm.

4. The rotation speed of the material controlling cam is equal to heat pressing cam, and the cams equilibrium is equal to medicament nest of heat pressing cam. Therefore it can have the distance from the plate edge the medicament nest and the one between the central medicament nest be equal.

5. The punch adopts electronic checking signal and PLC programs. It can change the number of granules at any time in the horizontal direction of the plate, making the user free to change the plates without replacing the moulds.

6. It can be equipped with an additional cursor tracking and registering plate system, inking wheel printer to have the products printed beautifully and uniformly, upgrading the products. The digit numbers are stamped more clearly.

Technical Data:

Speed of drum (rpm) | 7-15 stepless adjustable |

Capacity (pcs/h) | 10,000-45,000 pcs/h |

Max. Packing Width (mm) | 160mm can be manufactured as user's requirements |

Alu for Medicine(mm) | 0.15-0.1×160 |

AL/PL Complex Film(mm) | 0.08×160 |

Hole die of Reel (mm) | 40-45 |

Electro thermal Power | 1kw×2 |

Main Motor (kw) | Main Motor (kw) |

Air Pressure (Mpa) | 0.4 |

Air supply | ≥0.1m³/min |

Overall Dimensions(mm) | 1250×600×1470(L×W×H) |

Weight (kg) | 900 |

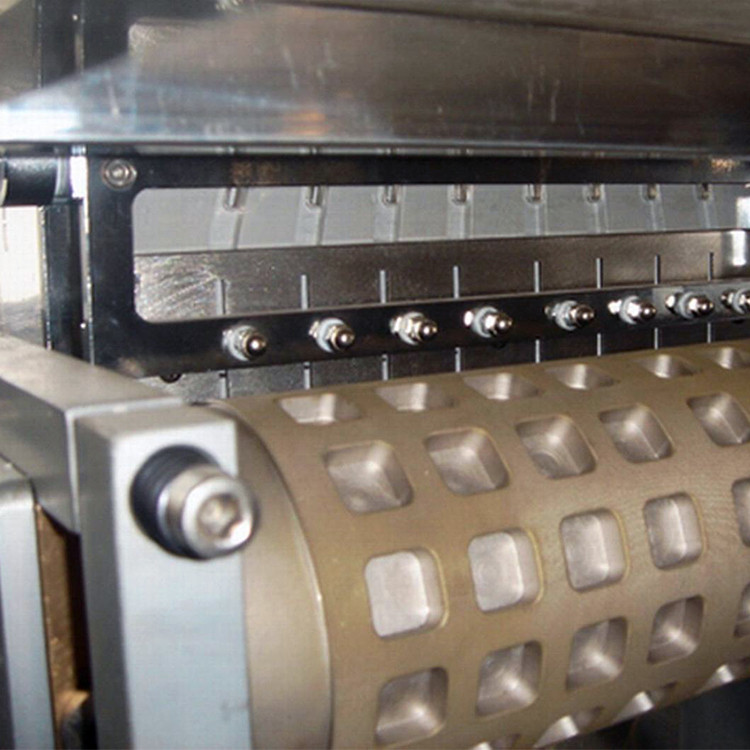

Machine Photo:

Blister Sample: