-

Difference between dry granulation and wet granulation-victor granulator?

time2019/11/14

PublisherXavier

-

Drying equipment is very widely used in industry, and the use of drying equipment is needed in many fields. Also, drying equipment also plays an important role in the pharmaceutical industry. Today, the author will bring eight kinds of drying equipment in the chemical and pharmaceutical industry. The application of eight drying equipments in chemical and pharmaceutical industry is analyzed.

time2019/11/15

PublisherXavier

-

Spray drying is one of the most remarkable technologies currently to be applied to pharmaceuticals. It is a continuous process that converts, in a single step, a liquid feed into a powder and is an ideal process when precise attributes such as particle size, morphology and stability are required. This review describes the technology, current and future applications and how the present level of understanding and modeling tools enable a process development stage that is both lean and risk-free.

time2019/11/18

PublisherXavier

-

Use of belt dryer is very wide, present in the pharmaceutical, food, biological, chemical and other fields already have it handy. However, in each area of its selection criteria is not the same, because the requirements and parameters of the dried material in various fields have a greater difference.

time2019/11/19

PublisherXavier

-

Although the belt dryer is relatively energy efficient dryer, but in practice there is a failure, and we have done is to identify the cause of the fault to be eliminated, so that belt dryer best energy efficiency for us service.

time2019/11/20

PublisherXavier

-

Coating tablets with a thin polymer film can be an effective way to give your products a professional edge. High quality tablets can be quickly and easily produced using a tablet coating machine and the correct excipients . Unfortunately several defects can arise with coatings. The following list provides helpful remedies for common issues that may be encountered.

time2019/11/21

PublisherXavier

-

The tablet making industry is currently going through a period of significant change. An increasing number of patents are expiring giving tool makers and tablet manufacturers plenty of opportunity to innovate in a range of technologies.

time2019/11/22

PublisherXavier

-

Pharmaceutical tablets may be defined as the solid unit dosage form of one or more medicaments with or without suitable excipients and prepared either by moulding or by compression.

time2019/11/25

PublisherXavier

-

A rapid mix granulator is a multi-purpose mixer/processor equally suitable for high speed dispersion of dry powders and their granulation with aqueous or organic solvents. The equipment is designed to achieve rapid mixing and the formation of consistent granules required for the production of high quality pharmaceutical tablets for solid dosage forms of medication. Good mixing and control of granule size leads to fast tableting speeds and high quality products with low rejection rate.

time2019/11/26

PublisherXavier

-

Fluid bed dryers. The average consumer has most likely never even heard of them. But in the world of bulk processing, fluid bed dryers have established themselves as dependable and multi-functional processors; capable of completing a variety of critical tasks.

time2019/12/02

PublisherXavier

-

Freeze dryer and lyophilizer are synonymous names for the same equipment. A freeze dryer executes a water removal process typically used to preserve perishable materials, to extend shelf life or make the material more convenient for transport. Freeze dryers work by freezing the material, then reducing the pressure and adding heat to allow the frozen water in the material to sublimate.

time2019/12/03

PublisherXavier

-

The coating process is important step in the manufacture of modern pharmaceutical tablets. The coating itself can serve several functions – it can strengthen the tablet, control the release of active ingredients, improve its taste, provide colour, make it easier to package and handle, and protect it from moisture. Sugar coating was one of the earliest methods developed to coat tablets and is still practised for some products, especially confectionery.

time2019/12/04

PublisherXavier

-

Tablets are solid dosage forms usually containing active pharmaceutical ingredient and excipients in powder, crystalline or granular form with or without diluents which is prepared either by moulding or compression process. Tablets are the most widely used solid dosage forms because of their advantages and popularity increasing day by day. Tablet usually contains filler, diluents, binders, lubricants, glidants, disintegrants, antiadherent, colouring agents and flavouring agents as excipients.

time2019/12/06

PublisherXavier

-

Freeze dryer and lyophilizer are synonymous names for the same equipment. A freeze dryer executes a water removal process typically used to preserve perishable materials, to extend shelf life or make the material more convenient for transport. Freeze dryers work by freezing the material, then reducing the pressure and adding heat to allow the frozen water in the material to sublimate.

time2019/12/09

PublisherXavier

-

when the machine works normally for a long time, the parts that are in direct contact with the drug should be cleaned regularly. When the drug batch is changed or the time of withdrawal is long, the parts should be cleaned regularly.

time2019/12/10

PublisherXavier

-

The fully automatic capsule filling machine consists of an empty capsule discharge device, a capsule distribution device, a powder discharge device, a metering plate mechanism, a capsule filling and sealing mechanism, a box main drive mechanism, and an electrical electrical control system.

time2019/12/11

PublisherXavier

-

Good manufacturing practice (GMP) is a system for ensuring that products are consistently produced and controlled according to quality standards. It is designed to minimize the risks involved in any pharmaceutical production that cannot be eliminated through testing the final product. Good manufacturing practice guidelines provide guidance for manufacturing, testing, and quality assurance to ensure that a food or drug product is safe for human consumption.

time2019/12/12

PublisherXavier

-

Tablet press belongs to a kind of pharmaceutical processing equipment, which is suitable for tablet pharmaceutical tablet forming. In the process of tablet pharmaceutical production, tablet press mold plays an important role in the quality of products.

time2019/12/13

PublisherXavier

-

Tablets are solid preparations made of tablets or special-shaped tablets after evenly mixed with drugs and excipients. Because they are simple to take and easy to carry, the market size of tablets has been growing continuously in recent years. The management and treatment of these common diseases, frequently-occurring diseases and chronic diseases are closely related to the use of tablets.

time2019/12/16

PublisherXavier

-

Check the machine parts regularly, 1-2 times a month. The inspection items are whether the worm wheel, worm, bearing, pressing wheel, crankshaft, upper and lower rail guide and other moving parts rotate flexibly and wear. If any defect is found, it shall be repaired and used in time.

time2019/12/17

PublisherXavier

-

Pharmaceutical tablet press is good or bad has a most reason is determined by the punching machine, in a nutshell is the punching machine is the core of the tablet press device, whether any form of tablet press, such as tablet tablet machine, high speed tableting machine, double tablet machine, double tablet machine, circular piece of tablet press, candy tablet press, etc., all need to be aware of is the installation of punching die!

time2019/12/23

PublisherXavier

-

Capsule filling machine integrates machine, electricity and gas. It adopts micro-computer programmable controller, touch panel operation, frequency conversion speed regulation, equipped with electronic automatic counting device, which can automatically complete the capsule positioning, separation, filling, locking and other actions, reduce labor intensity, improve production efficiency, and meet the requirements of pharmaceutical hygiene.

time2019/12/24

PublisherXavier

-

Disassembly And Installation Of Main Parts Of Small Powder Tablet Press

time2019/12/25

PublisherXavier

-

There are many factors that affect the quality of the automatic capsule filling machine, among which the powder filling mechanism and the positions of the capsule turret are important factors. In the aspect of powder filling mechanism, the powder filling mechanism is mainly composed of 6 equal parts of intermittent rotary movement metering plate, 6 groups of axial movement punch rod (adjustable axial position) and powder screw automatic feeder.

time2019/12/26

PublisherXavier

-

The coating process of sugar-coated tablets is complex, time-consuming and prone to many problems, such as cracks, bare edges, hemp noodles, patches and so on. Sugar coating has gradually been replaced by film coating, the following is only the film coating problem.

time2019/12/31

PublisherXavier

-

In the pharmaceutical production process, the molds used for tablet pressing play a vital role in the quality of tablets. The length of impact body is different, which directly affects the weight difference and hardness of tablet, or affects the brittleness; Punch edge knock edge or punch is not flat, the impact of one - sided caused by split, stick and so on.

time2020/01/09

PublisherXAVIER

-

Granulation is the main manufacturing process for the manufacturing of tablets. It is of two types wet and dry that is adopted on the basis of the API used in the manufacturing.

time2020/03/03

PublisherXAVIER

-

Importance of mixing time and effects of extended mixing time on blend uniformity and pharmaceutical product quality.

time2020/03/17

-

Different types of tablets need different coating according to the nature and properties of the tablets.Coating of tablets helps to protract the tablets from environmental conditions on the other hand it improves the taste of tablets.

time2020/03/22

-

Wet granulation forms by binding the powders together with an adhesive, instead of by compaction. bridges are developed between the particles and the tensile strength of bonds increases as the amount of liquid added is increased.

time2020/03/23

-

Coronavirus disease (COVID-19) advice for the public When and how to use masks

time2020/03/30

PublisherSteve

-

The manufacture of orally dissolving films is done by various methods such as solvent casting, hot-melt extrusion, semisolid casting, solid-dispersion extrusion, and rolling. The authors discuss these methods and the various parameters in which dissolving films are evaluated.

time2020/04/10

PublisherSteve

-

In the process of pressing, there are often problems such as sticking and punching. When pressing the tablet, the fine powder on the surface of the tablet is adhered by the punch or die, but the surface is not smooth, uneven and dented. The inspection punch often has the fine powder sticking, which is called stick punching.

time2020/04/21

PublisherSteve

-

Mother Earth is clearly urging a call to action. Nature is suffering. Australian fires, heat records and the worst locust invasion in Kenya. Now we face COVID -19, a worldwide health pandemic link to the health of our ecosystem.

time2020/04/22

PublisherSteve

-

Now more than ever, at a time when globally most schools are closed and people are having to limit time spent out of their homes, the power of books can be leveraged to combat isolation, to reinforce ties between people, and to expand our horizons, while stimulating our minds and creativity.

time2020/04/23

PublisherSteve

-

Common faults and solutions of tablet press machine

time2020/04/26

PublisherSteve

-

In the pharmaceutical industry, the capsule filling machine is a kind of commonly used equipment, which can carry out automatic transmission, seeding, filling, locking and other processes for capsules.

time2020/05/12

PublisherSteve

-

Cracking in tablets during the compression is a major problem in tablet manufacturing. Some causes and solutions of the cracking of tablets are given here.

time2020/05/25

PublisherSteve

-

The filling speed of capsule filling machine is faster and the size difference of capsule filling machine is small. In addition, capsule filling machine has many advantages, such as fast arrangement speed, high efficiency, simple operation, convenient maintenance, low power consumption and so on. It is the first choice capsule filling machine for pharmaceutical factory, health product factory, hospital preparation room.

time2020/05/25

PublisherSteve

-

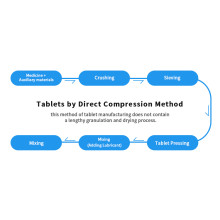

Direct compression method of tablet manufacturing is widely used because it is a time saving process. this method of tablet manufacturing does not contain a lengthy granulation and drying process.

time2020/05/26

PublisherSteve