-

Tablet coating machines work on the simple principle of applying the coating ingredients in the form of a solution to a group of tablets in a bed that may move horizontally or vertically. A concurrent flow of heated air helps to evaporate the solvent. The coating is equally distributed to the tablets through the movement of the bed.

time2020/05/28

PublisherSteve

-

Effervescent tablet pressing machine is a kind of automatic rotating and continuous tablet pressing machine. It is also a special equipment for chemical, food, electronic and other industrial enterprises to press granular raw materials into tablets or granules, which is suitable for small batch production.

time2020/06/19

PublisherSteve

-

A single station tablet press is a simple mechanical machine that can be used to compress powder into tablets that are uniform in size, shape and weight. The machine is used for low-volume production of tablets for a wide range of applications from cosmetics and pharmaceuticals to cleaning products.

time2020/06/19

PublisherSteve

-

In the customized orders of users, the diversified requirements for the structure of the tablet press are mainly manifested in the following aspects:

time2020/06/22

PublisherSteve

-

In the customized orders of users, the diversified requirements for the structure of the tablet press are mainly manifested in the following aspects:

time2020/06/22

PublisherSteve

-

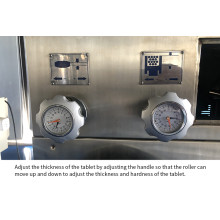

The filling dose adjustment on the rotary tablet press is mainly based on the filling rail. By rotating the dial regulating plate, the shaft can be driven to rotate, and the worm shaft connected with it also rotates.

time2020/06/29

PublisherSteve Chan

-

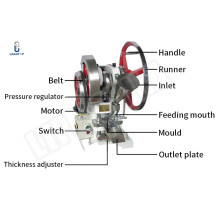

The tablet press is a machine that puts granular or powdery materials in the die hole and presses them into tablets.

time2020/07/30

PublisherSteve Chan

-

The purpose of coating is to improve the appearance of the tablet, prevent moisture, avoid light, cover up bitterness or unpleasant odor, and control the release location and release rate of the drug.

time2020/07/30

PublisherSteve

-

In the pharmaceutical industry, the single punch tablet machine can be said to be an indispensable processing equipment, usually used to compress various Chinese medicine tablets, western medicine tablets, etc.

time2020/07/30

PublisherSteve

-

In the process of medicine and other industrial production, mixer is a common equipment. Its function is to mix two or more materials evenly. In recent years, with the rapid development of pharmaceutical industry, mixer equipment also ushered in the objective market prospects. At present, three-dimensional mixer and two-dimensional mixer are common in the market.

time2020/07/30

PublisherSteve

-

Granulation refers to the operation of processing materials in the state of powder, melt, aqueous solution, etc. into granules with a certain shape and size. At present, the granulation processes used by pharmaceutical companies include extrusion granulation and shear granulation.

time2020/07/30

PublisherSteve

-

The pharmaceutical industry is a high-pollution industry. In recent years, with the advancement of environmental protection policies, there are not a few pharmaceutical companies that have "slopped" on environmental issues. Due to the difficulty and high cost of pollution control. At present, how to solve the problem of economic and environmental benefits has become a topic that pharmaceutical companies have to face.

time2020/08/03

PublisherSteve

-

It is reported that some pharmaceutical companies in the process of producing capsules, due to the fine powder, will produce appearance defects during machine filling, which has always been required to remove by manual "drug selection". Through continuous optimization and debugging of the capsule filling equipment, the product rate of appearance defects is reduced, and the labor cost is greatly reduced.

time2020/08/12

PublisherSteve Chan

-

In the production of solid preparation tablets, mixing and granulation are the key to determine the quality of compression tablets or capsules. In a sense, granulation is the key basis. In the past, wet granulation equipment was widely used in the industry, but now wet granulation equipment has developed to high-speed mixing granulator, which is a kind of solid preparation pharmaceutical equipment which develops rapidly in recent years.

time2020/08/18

PublisherSteve

-

In the production process of granule medicine, granulator such as dry granulator plays a key role. It is understood that the dry granulator can meet the requirements of one-step granulation, integrate the tedious processing links together, and carry out completely closed processing, so that the appearance of the processed granule medicine is improved, and it is easy to store and transport.

time2020/08/26

PublisherSteve

-

What should be done if the pressed tablets can not be disintegrated within the prescribed time limit

In the production process of the tablet press machine, there are often cases where the compressed tablets cannot be disintegrated within the prescribed time limit, which affects the dissolution, absorption and efficacy of the drug. What is going on? How to solve it?

time2020/08/26

PublisherSteve

-

Vibrating fluidized bed is a conventional equipment for drying in pharmaceutical industry, which belongs to the type of convective drying. The working mechanism of the convective dryer is that the heat is directly transferred to the wet materials by hot air in the form of convection, and the water vapor is taken away at the same time when the moisture vaporizes. Besides the dryer itself, the device also has fan, heater, separator and other auxiliary equipment.

time2020/09/09

PublisherSteve

-

Spray dryer is easy to operate, excellent in performance and excellent in manufacturing, especially in meeting the requirements of GMP in pharmaceutical and food industries. It is welcomed by users in the pharmaceutical and food industries.

time2020/09/09

PublisherSteve

-

Spray dryer is a device that can dry and granulate at the same time. It mainly consists of slurry supply system, atomizer, drying tower, hot air system, exhaust gas and dust removal system, unloading and powder conveying system.

time2020/09/16

PublisherSteve

-

At present, there are spiral belt mixer, cone mixer, V-type mixer and three-dimensional mixer which are popular in the market. For mixer users, the quality, uniformity and efficiency of mixing materials are the main concerns, among which the efficiency has attracted much attention in recent years. Therefore, improving the efficiency of mixer is the key to win in the market. What factors can we improve the efficiency of the mixer? The author summarizes the following aspects.

time2020/09/21

PublisherSteve

-

A tablet press, also known as a tablet compressing machine or tableting machine, is used to compress pharmaceutical powder formulations into tablet form, creating tablets of uniform size, shape and weight. The tablet press may also be used for the manufacture of products in the form of tablets for other sectors such cosmetics, cleaning products and catalysts for the petrochemical industry.

time2020/09/23

PublisherSteve

-

Fluid bed granulator is also called one-step granulator. It is a machine which can complete the mixing, granulation and drying of conventional wet granulation in a closed container at one time. The Fluid bed granulator can keep the drug powder in suspension fluidization state under the action of bottom-up air flow. The adhesive liquid will be sprayed into the fluidization chamber from the upper or lower part, and the powder will agglomerate into particles.

time2020/09/23

PublisherSteve

-

Mixing is an indispensable production process in modern industry. With the continuous development of industry, the development of mixer will be more and more powerful. Mixer covers the entire industrial field, such as chemical industry, food, building materials, medicine, chemical fertilizer. There are many kinds of powder mixing equipment. The advantages and disadvantages of mechanical mixing equipment are analyzed below.

time2020/10/10

PublisherSteve

-

Many pharmaceutical, chemical, light industry and other industries will use mixing equipment, mainly including: V-type mixer, double cone mixer, 2D mixer and 3D mixer, etc. Among them, 3D mixer occupies an important position.

time2020/10/19

PublisherSteve

-

Spray dryer is a drying equipment for treating solution, suspension or slurry material. It can be directly dried from liquid to powder, which is the biggest advantage of spray dryer. Its low thermal efficiency, large volume, low production capacity and high investment are its shortcomings. Spray drying machine is widely used in chemical industry, light industry and food industry because it can be directly obtained from solution or suspension system with uniform powder products.

time2020/10/28

PublisherSteve

-

Vibrating fluidized bed is a conventional equipment for drying in pharmaceutical industry, which belongs to the type of convective drying. The working mechanism of the flow dryer is that the heat is directly transferred to the wet material by hot air convection, and the water vapor is taken away at the same time when the moisture vaporizes. Besides the dryer itself, the device also has fan, heater, separator and other auxiliary equipment.

time2020/10/28

PublisherSteve

-

In pharmaceutical products, solid preparation is a kind of dosage form with wide application and variety, accounting for about 70% to 80%. In order to ensure the product quality and smooth production process of solid preparation, it is often necessary to process and treat the drug, including crushing, grading, mixing, granulation, drying, tablet pressing, etc., and the application of powder technology is permeated in each unit operation.

time2020/10/29

PublisherSteve

-

Pharmaceutical manufacturers should consider the following factors in selecting tablet press:The variety, grade and added value level of the products produced. The size of the shift output. Workshop area.

time2020/11/05

PublisherSteve

-

High speed centrifugal spray dryer is one of the most popular equipment in drying equipment. It is suitable for special drying methods of emulsification, suspension, paste, liquid and other equipment. The centrifugal spray dryer has ideal effect and high efficiency. The size of the dust particles does not need to increase the grinding process. At present, high-speed centrifugal spray dryer is widely used in chemical industry, light industry, food industry and so on.

time2020/11/10

PublisherSteve

-

In medicine, chemical industry, food and other fields, spray dryer is a common material drying equipment, playing a major role. Data show that in 2017, the total market size of the global spray dryer was US $1 billion 68 million, and the market scale increased steadily in recent years. It is estimated that the market will reach US $1 billion 611 million by the end of 2025.

time2020/11/16

PublisherSteve

-

The tablet press is a kind of machine which puts the particles or powder materials in the mold hole and presses them into tablets by punch. It is especially suitable for small batch production. It is characterized by adjustable speed, filling depth of materials, sheet shape thickness and mechanical buffer installed on the machine, which can avoid dust generated during operation, prevent sticking and blocking, and recycle raw materials for reuse.

time2020/11/24

PublisherSteve

-

In the next five years, continuous production mode may become the development direction of solid preparation industry

time2020/11/27

PublisherSteve

-

Regarding the fully automatic capsule filling machine, what operating specifications and maintenance methods we usually need to pay attention to, the following editor will take you to learn more.

time2020/12/03

PublisherSteve

-

In winter, the temperature is greatly reduced, people often put on thick coats and hats to keep warm, in order to prevent sick cold. In fact, as people are afraid of cold, in the low temperature season, pharmaceutical machines also need to do a good job in heat preservation and antifreeze measures to ensure the stable operation of the equipment. So, what are the anti freezing measures for pharmaceutical machines?

time2020/12/07

PublisherSteve

-

2020 is coming to an end. For the coming year 2021, I believe that many pharmaceutical machinery people are full of expectations and are fully prepared. Looking back on the development trend of pharmaceutical equipment industry in 2020, the author thinks that four key words can be used to define the concept, which are internationalization, high-end, customized and intelligent.

time2020/12/15

PublisherSteve

-

Regarding the fully automatic capsule filling machine, what operating specifications and maintenance methods we usually need to pay attention to, the following editor will take you to learn more.

time2020/12/17

PublisherSteve

-

In the process of pharmaceutical production, bottle washing machine is also an indispensable part, and the technology of domestic bottle washing machine has reached a very mature level. However, there are often feedback from users that the washing effect of bottle washing machine is not ideal after using for a period of time, which can not meet the requirements of production. So, what's going on? What are the reasons? How to solve this problem?

time2020/12/22

PublisherSteve

-

Focusing on the production of solid pharmaceutical preparations, granulation is an important process

There are many kinds of drugs, which can be divided into solid, semi-solid, liquid and gas dosage forms. Among them, solid preparation accounts for about 70% of all drugs, which is the main dosage form of drugs. It has the advantages of good physical and chemical stability, low production cost, easy to take and carry, so it is welcomed by patients.

time2020/12/29

PublisherSteve

-

The common faults of semi-automatic capsule filling machine are described below. The vibration of capsule filling machine is not ideal and the voltage is adjusted. Reed screw loose, tighten screw. The capsule shell is arranged in the workbench plate, the mouth is high or low, and the dislocation plate and guide rail are adjusted.

time2021/01/06

PublisherSteve

-

The tablet press punching die is also the most commonly used tablet equipment tablet press on an indispensable accessory. It is also a very important work to choose the appropriate punching die correctly after the purchase of the tablet press. In many tablet pharmaceutical factories, the tablet press purchased can not be used normally because of the improper selection of the punching die. .

time2021/01/11

PublisherSteve